Understanding Castor loadings for different configurations

A quick guide to calculating castor load capacities in these different configurations. It is important for efficiency and safety to get the load calculations right. If you would like any expert help and guidance with castor load capacities, please call us on 01282 424376 or email [email protected]

In certain instances, it’s beneficial to use a mixture of castor configurations to get the ideal solution for your application and environment.

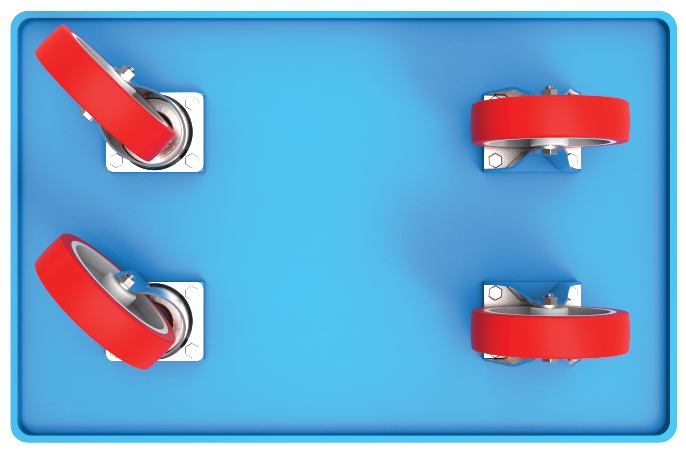

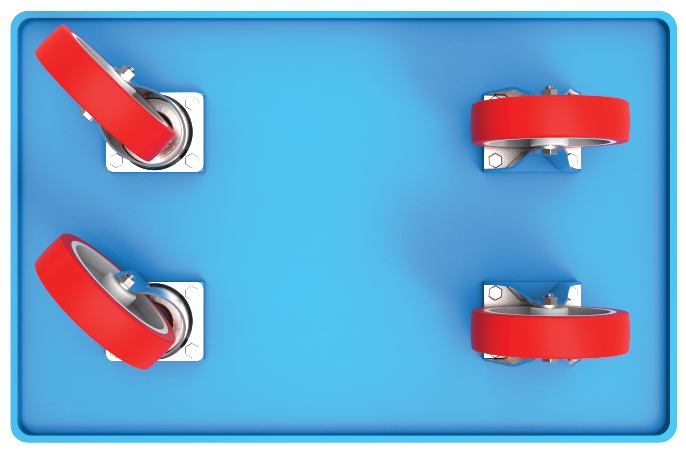

Two swivel & two fixed

This option offers the safest handling and load control with good steering for straight runs and cambers. When moving, the two fixed castors should lead with the swivel castors at the back. This configuration works for most loads. Each castor load capacity should be calculated to be at least 33% of total load as when in motion one or other of the castors may lose contact on uneven floors thus putting its load onto the other castors.

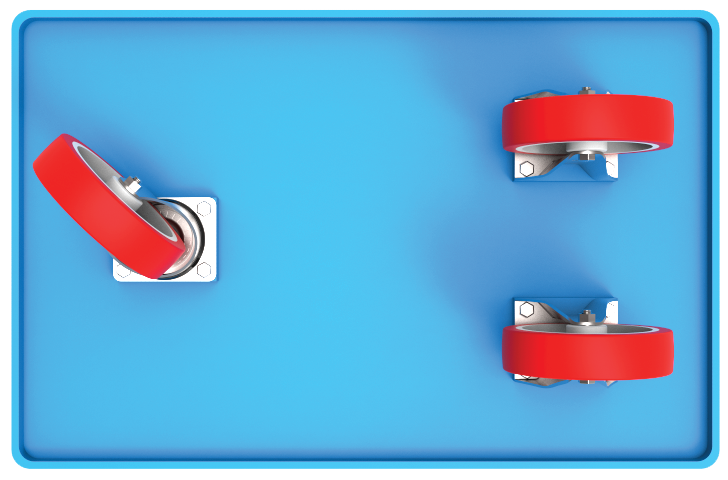

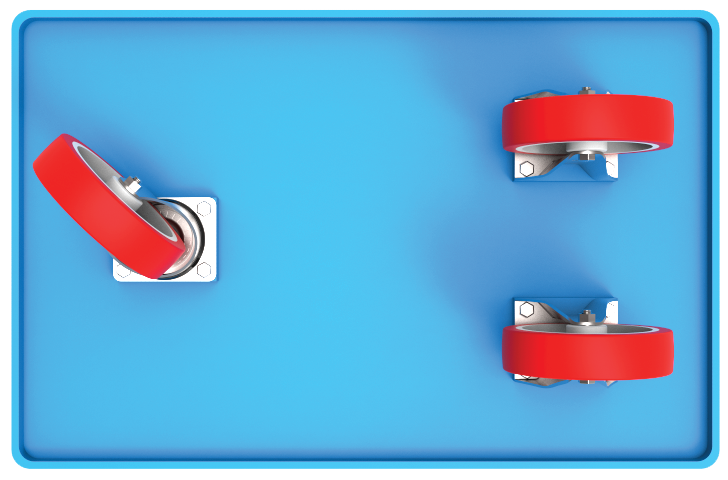

One swivel & two fixed

Configuration will provide easy manoeuvrability but is only recommended for lighter loads. To ensure safe handling and avoid tipping loads must he distributed evenly. For this option, calculate the castor load capacity to be a minimum of 40% of the total load weight.

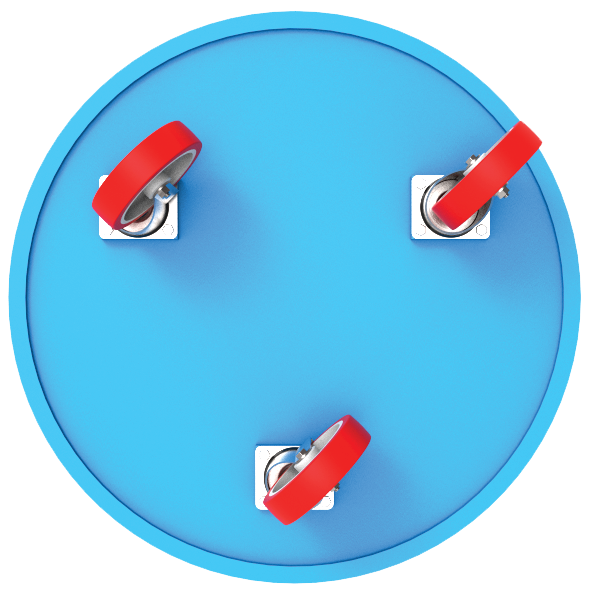

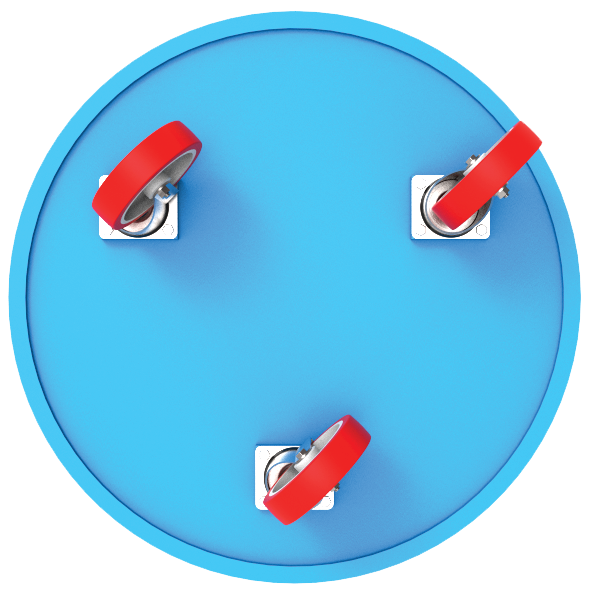

Three swivel

This option allows maximum manoeuvrability, but will be difficult to control on straight runs, and sloping or uneven surfaces. This configuration is advised only for smaller trolleys with light loads. For this option calculate castor load capacity to be a minimum of 40% of the total load weight.

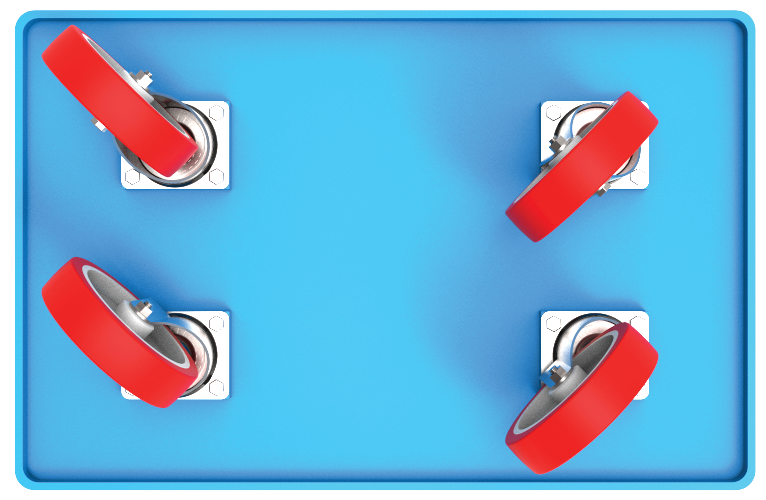

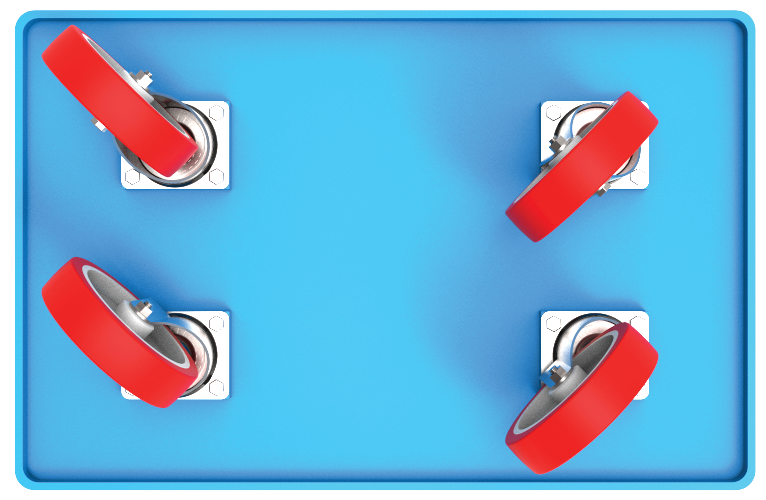

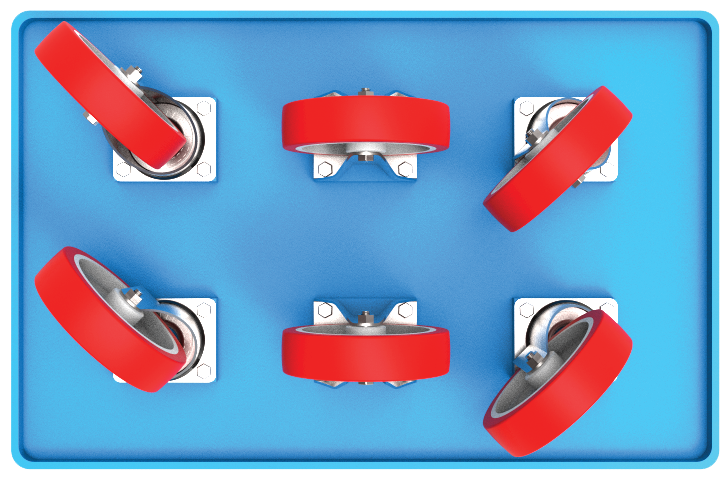

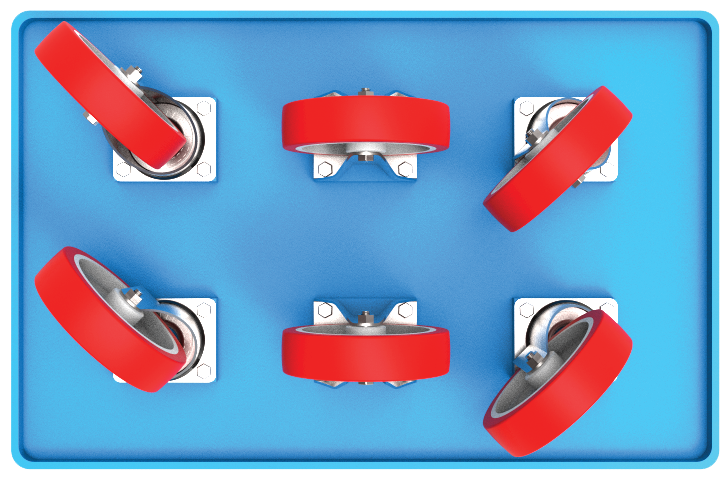

Four swivel

This will provide you maximum manoeuvrability and is ideal for smaller spaces. But will be harder to control on longer straight runs, or sloping and uneven surfaces, this will be noticeable with heavier loads. This can be addressed by using castors with directional locks (please contact us for further information). The load capacity for each castor should be calculated to be at least 33% of total load as, when moving one or other castors may lose contact on uneven surfaces putting its load onto the remaining castors.

Four swivel & two fixed, centrally pivoting

This option is primarily used on longer trolleys to optimise control and manoeuvrability. The two central fixed castors are usually one size larger or the same size as the swivel castors and fitted with 25mm packing under the top fixing plate. The capacity for the fixed castors should be at least 50% of total gross load. Swivel castor loads will vary.

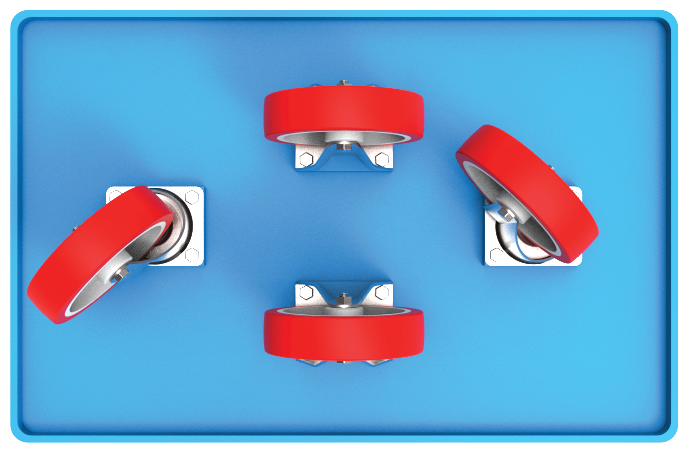

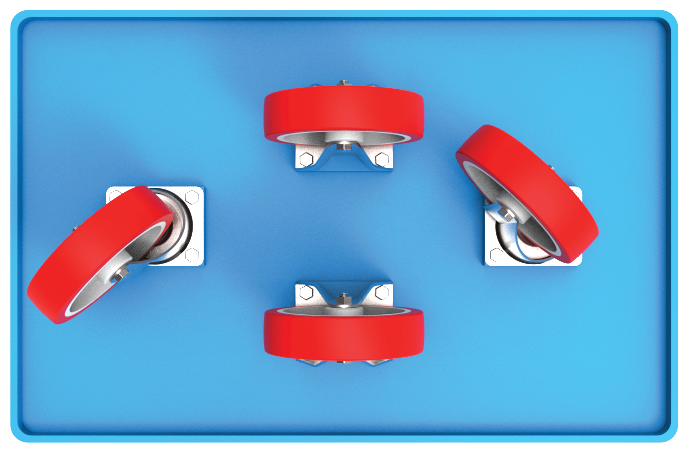

Two swivel & two fixed, centrally pivoting

Like the 4 swivel & 2 fixed option but less stable if the load is not evenly distributed. The two central fixed castors are usually the same size as the swivel or one size larger and fitted with a 25mm packing under the top fixing plate. The capacity for the fixed castors should be at least 50% of total gross load. Swivel castor loads will vary.